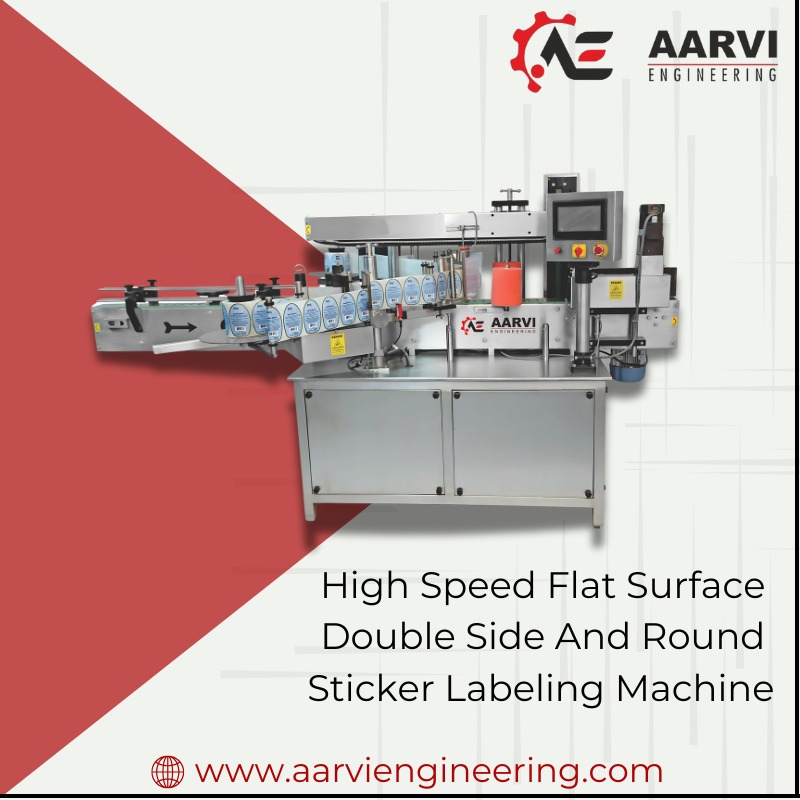

Servo model of flat surface double-sided sticker labelling machine by Aarvi Engineering > Conveyor system For reliable flat product movement, a servo motor regulates the conveyor belt's speed and direction. >Product deduction Every product on the conveyor is located using optical or photoelectric sensors. In order to initiate the labelling procedure at the appropriate moment, the sensors provide this data to the control system. >Label Applicators: The movement of the label applicator is accurately controlled by servo motors. These motors enable positional and speed changes to guarantee that the labels are placed at the proper angle and spot. Two label applicators, one for each side of the product, are included in a double-sided labeling machine. To guarantee precise and reliable label installation on both sides, servo motors regulate the heads' relative positions to the goods. Servo motors can change the labeling heads' height and distance for various products according to their size or type. >Safety Features: In order to protect operators in the event of a malfunction, servo-based systems frequently feature emergency stop mechanisms connected to sensors. Safety elements, like guards around moving parts, can be incorporated into the servo model to avoid unintentional contact. >PLC and Servo Controller: The PLC acts as the machine's brain, organizing sensor signals, managing overall machine performance, and operating servos for conveyor and applicator motions. By using signals from the PLC to operate each servo, these drives make sure that all motors move smoothly and in unison.

Chat with us on WhatsApp

×

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

https://www.aarviengineering.in/latest-update/servo-model-of-flat-surface-double-sided-sticker-l/89

Servo model of flat surface double-sided sticker l...

2025-01-07T05:09:42

Servo model of flat surface double-sided sticker labelling machine by Aarvi Engineering > Conveyor system For reliable flat product movement, a servo motor regulates the conveyor belt's speed and direction. >Product deduction Every product on the conveyor is located using optical or photoelectric sensors. In order to initiate the labelling procedure at the appropriate moment, the sensors provide this data to the control system. >Label Applicators: The movement of the label applicator is accurately controlled by servo motors. These motors enable positional and speed changes to guarantee that the labels are placed at the proper angle and spot. Two label applicators, one for each side of the product, are included in a double-sided labeling machine. To guarantee precise and reliable label installation on both sides, servo motors regulate the heads' relative positions to the goods. Servo motors can change the labeling heads' height and distance for various products according to their size or type. >Safety Features: In order to protect operators in the event of a malfunction, servo-based systems frequently feature emergency stop mechanisms connected to sensors. Safety elements, like guards around moving parts, can be incorporated into the servo model to avoid unintentional contact. >PLC and Servo Controller: The PLC acts as the machine's brain, organizing sensor signals, managing overall machine performance, and operating servos for conveyor and applicator motions. By using signals from the PLC to operate each servo, these drives make sure that all motors move smoothly and in unison.

2025-01-07T05:09:42

Keywords

- fully automatic flat surface both side with round sticker labelling machine manufacturer by aarvi engineering

- fully automatic flat surface both side with round sticker labelling machine manufacturer in gujarat

- fully automatic flat surface both side with round sticker labelling machine manufacturer in ahmedabad

- fully automatic flat surface both side with round sticker labelling machine in ahmedabad

- fully automatic flat surface both side with round sticker labelling machine by Aarvi engineering

- fully automatic flat surface both side with round sticker labelling machine in gujarat

- fully automatic flat surface both side with round sticker labelling machine

- high speed flat surface double side and round sticker labelling machine

- heads relative positions

- labeling heads height

- type safety features

- motors enable positional

- motors move smoothly

- doublesided labeling machine

- reliable label installation

- sensors safety elements

- servo motor regulates

- goods servo motors

- direction product deduction

- conveyor belts speed

- servo motors

- machine performance

- photoelectric sensors

- sensors provide

- label applicator

- label applicators

- servo model

- servo controller

- labelling procedure

- accurately controlled

- proper angle

- protect operators

- moving parts

- operating servos

- applicator motions

- drives make

- guarantee precise

- plc acts

Submit Your Enquiry