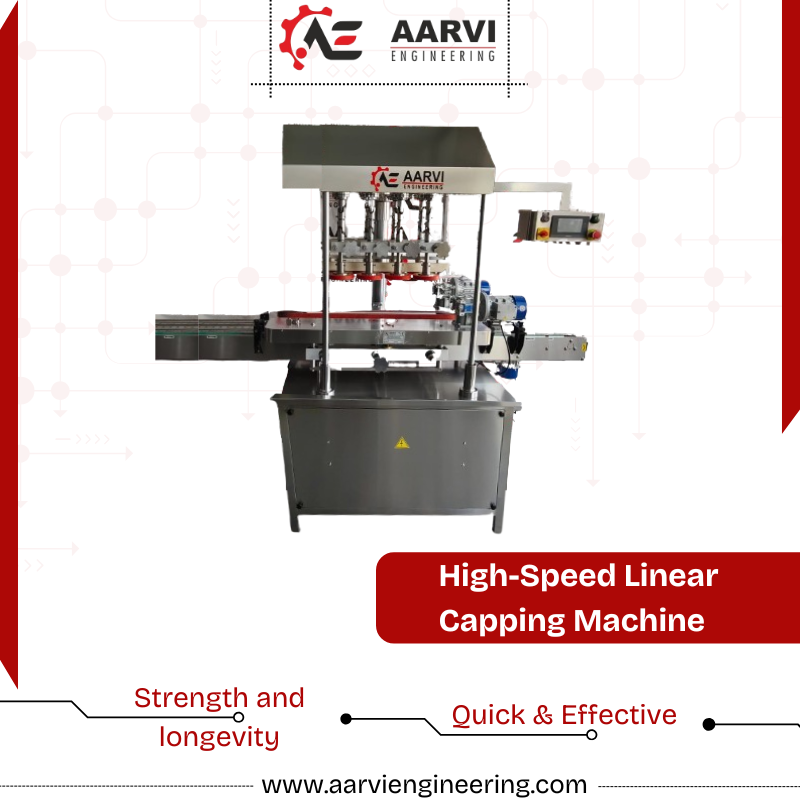

High-Speed Linear Capping Machine by Aarvi Engineering.A High-Speed Linear Capping Machine is an automated device that can attach caps to bottles, jars, or other containers quickly and precisely. These devices are frequently employed in sectors where high-volume capping is crucial to preserving industrial process efficiency, including food and beverage, pharmaceutical, cosmetic, and chemical industries. >>Linear Motion: Containers (such bottles or jars) are moved through the capping process by the machine using a linear conveyor system. Throughout the several capping phases, every container is positioned in a straight line. >>Conveyor Feeding System: A conveyor belt transports the containers from one station to the next as they are fed into the system. >>Cap Sorting and Feeding: Caps are automatically sorted into their proper positions after being stored in a hopper. The caps are fed onto the containers using an automated feeding device. >>Cap Placement: The capping heads take up and attach the cap to the container. They usually have a range of cap applicators (such as screw cap, snap-on, and press-on). To properly align the caps for automatic installation, certain systems might include a vibratory system. >>Cap Tightening: The machine tightens or seals the cap after it has been placed on the container using torque mechanisms or specialized capping heads. Leaks and spills can be avoided by adjusting the torque to guarantee the proper degree of tightness. >>Quality Check: Inspection devices are built into some high-speed linear capping machines to find loose, missing, or misaligned caps. This keeps the product's quality and integrity intact as it operates at high speed.

Chat with us on WhatsApp

×

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

High-Speed Linear Capping Machine by Aarvi Engi...

2025-02-15T09:02:13

High-Speed Linear Capping Machine by Aarvi Engineering.A High-Speed Linear Capping Machine is an automated device that can attach caps to bottles, jars, or other containers quickly and precisely. These devices are frequently employed in sectors where high-volume capping is crucial to preserving industrial process efficiency, including food and beverage, pharmaceutical, cosmetic, and chemical industries. >>Linear Motion: Containers (such bottles or jars) are moved through the capping process by the machine using a linear conveyor system. Throughout the several capping phases, every container is positioned in a straight line. >>Conveyor Feeding System: A conveyor belt transports the containers from one station to the next as they are fed into the system. >>Cap Sorting and Feeding: Caps are automatically sorted into their proper positions after being stored in a hopper. The caps are fed onto the containers using an automated feeding device. >>Cap Placement: The capping heads take up and attach the cap to the container. They usually have a range of cap applicators (such as screw cap, snap-on, and press-on). To properly align the caps for automatic installation, certain systems might include a vibratory system. >>Cap Tightening: The machine tightens or seals the cap after it has been placed on the container using torque mechanisms or specialized capping heads. Leaks and spills can be avoided by adjusting the torque to guarantee the proper degree of tightness. >>Quality Check: Inspection devices are built into some high-speed linear capping machines to find loose, missing, or misaligned caps. This keeps the product's quality and integrity intact as it operates at high speed.

2025-02-15T09:02:13

Keywords

- High speed linear capping machine manufacturer in ahmedabad

- High speed linear capping machine manufacturer in gujarat

- High speed linear capping machine manufacturer in india

- High speed linear capping machine in Ahmedabad

- High speed linear capping machine in india

- High speed linear capping machine in gujarat

- High speed linear capping machine by Aarvi engineering

- beverage pharmaceutical cosmetic

- linear conveyor system

- conveyor belt transports

- system cap sorting

- screw cap snapon

- automated device

- frequently employed

- highvolume capping

- capping process

- capping phases

- automatically sorted

- proper positions

- capping heads

- cap applicators

- properly align

- automatic installation

- proper degree

- products quality

- integrity intact

- high speed

- feeding caps

- misaligned caps

- machine tightens

- torque mechanisms

- attach caps

- bottles jars

Submit Your Enquiry