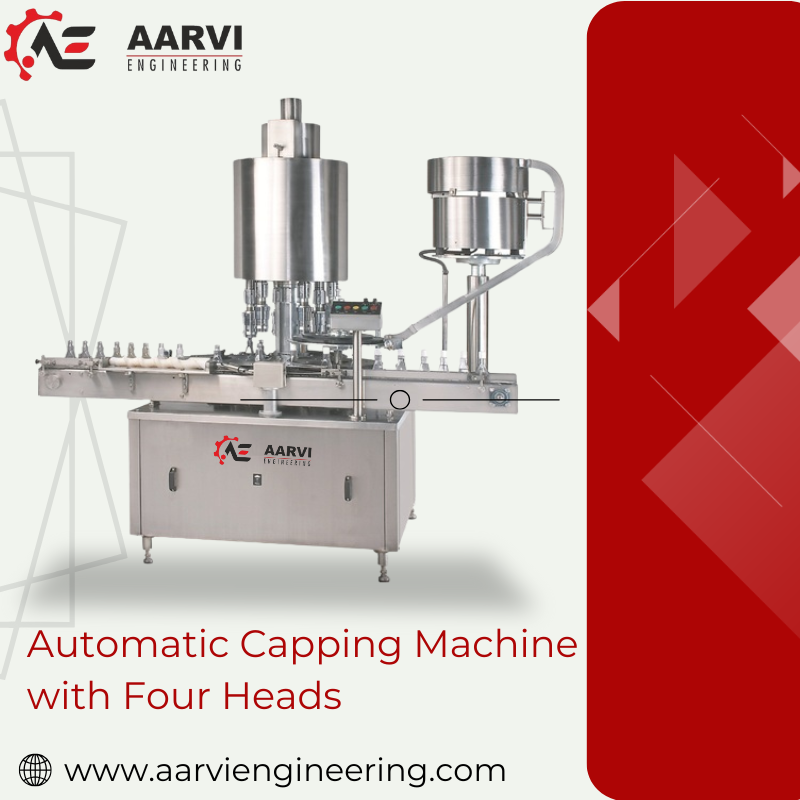

Aarvi Engineering Automatic 4 Head Rotary Capping Machine > For effective bottle in a variety of sectors, automatic four-head capping machines are indispensable. These devices are made to increase production efficiency and guarantee uniform sealing quality for all kinds of caps and containers. 1. Versatility :- Adaptable to a variety of goods, such as dry syrup, edible oils, shampoos, medications, and cosmetics. 2. Speed :- Depending on the size and kind of container, production rates can vary greatly; some machines can produce up to 120 bottles or vials each minute. 3. Construction :- Usually constructed of stainless steel for longevity and cleanliness, these devices frequently have height-adjustable shelves to suit a range of bottle sizes. > Technology :- A lot of versions come with cutting-edge features like No Bottle- No Cap, which stops capping when there isn't a container present. > Variable Frequency Drive :- Enables speed modifications according to production requirements. > Digital Counters :- To monitor the output of production In conclusion : An essential piece of machinery in contemporary manufacturing, the automatic four-head capping machine offers flexibility, dependability, and efficiency in a range of applications. These devices keep changing as a result of technological breakthroughs, providing improved functionality that satisfies the industry's expanding needs.

Chat with us on WhatsApp

×

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

Aarvi Engineering Automatic 4 Head Rotary Cappi...

2024-12-31T04:22:53

Aarvi Engineering Automatic 4 Head Rotary Capping Machine > For effective bottle in a variety of sectors, automatic four-head capping machines are indispensable. These devices are made to increase production efficiency and guarantee uniform sealing quality for all kinds of caps and containers. 1. Versatility :- Adaptable to a variety of goods, such as dry syrup, edible oils, shampoos, medications, and cosmetics. 2. Speed :- Depending on the size and kind of container, production rates can vary greatly; some machines can produce up to 120 bottles or vials each minute. 3. Construction :- Usually constructed of stainless steel for longevity and cleanliness, these devices frequently have height-adjustable shelves to suit a range of bottle sizes. > Technology :- A lot of versions come with cutting-edge features like No Bottle- No Cap, which stops capping when there isn't a container present. > Variable Frequency Drive :- Enables speed modifications according to production requirements. > Digital Counters :- To monitor the output of production In conclusion : An essential piece of machinery in contemporary manufacturing, the automatic four-head capping machine offers flexibility, dependability, and efficiency in a range of applications. These devices keep changing as a result of technological breakthroughs, providing improved functionality that satisfies the industry's expanding needs.

2024-12-31T04:22:53

Keywords

- automatic rotary capping machine manufacturer

- high speed rotary capping machine in gujarat

- high speed rotary capping machine in ahmedabad

- high speed rotary capping machine in india

- automatic rotary capping machine in gujarat

- automatic rotary capping machine in ahmedabad

- automatic rotary capping machine in india

- high speed rotary capping machine

- automatic rotary capping machine

- rotary capping machine

- container production rates

- bottle sizes technology

- increase production efficiency

- effective bottle

- vary greatly

- minute 3 construction

- stainless steel

- heightadjustable shelves

- cuttingedge features

- stops capping

- essential piece

- contemporary manufacturing

- industrys expanding

- devices frequently

- 120 bottles

Submit Your Enquiry